Remote monitor your Davis Anemometer with RMS

If you need to know how fast the wind is blowing, an anemometer is the device you need. An

anemometer is a meterorological device that calculates the speed of wind. Anemometers range

in size and price. There are two main types of anemometers, cup style and windmill style.

Other types of anemometers that are less common include Hot-wire style, Laser Doppler

style, and Sonic style. Most anemometers come with some kind of gauge or LCD readout that

displays the wind speed. But what if you want to monitor the wind speed remotely over an

Internet connection? RMS to the rescue!

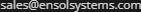

This project makes use of the GPIO pins on the RMS-200 board

to count the pulses from the anemometer. An RMS-200

voltmeter is used to measure the wind direction. We chose the popular Davis model 7911 cup

style anemometer because it is inexpensive and fairly accurate.

The anemometer kit includes bolts and brackets to fasten the anemometer to a pole or

building. The anemometer comes with 40 feet of 4-wire cable that has a common phone (RJ-11)

connector at the end. A surface mount modular jack was purchased so that the anemometer

cable could easily plug in without splicing into the anemometer cable.

Wind Speed

Theory of operation: There is a magnet in the wind cup assembly and a reed switch in

the head assembly. When the wind cup magnet is over the reed switch, the switch closes

causing the GPIO line on the RMS-200 board to be pulled low. When the magnet passes the

reed switch, the switch opens again causing the GPIO line to go high again. The RMS-200

counts these high to low transitions and writes the pulse count to a file approximately

every 2.25 seconds. The pulse count is the wind speed in MPH.

Below is a wiring diagram illustrating how the anemometer is hooked up to the RMS-200

board.

NOTE: A pull up resistor must be used to pull the RMS-200 GPIO pin high. A resistor

value of 4k to 20k can be used. Use the higher resistance value when the wiring to the

anemometer is short, and the lower value when the wiring is long or subject to leakage or

noise.

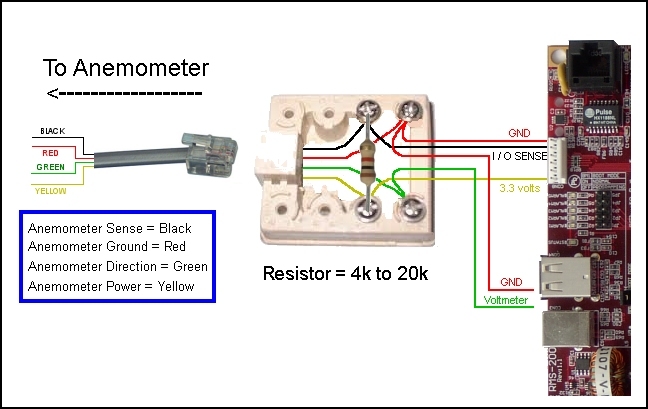

Below is the pin-out of the GPIO port (CON8) on the RMS-200 board. A six pin connector with

ribbon cable was used to interface the RMS-200 board to the modular jack. Only three wires

are used from the ribbon cable, VDD3.3, GND, and GPIO4.

Wind Direction

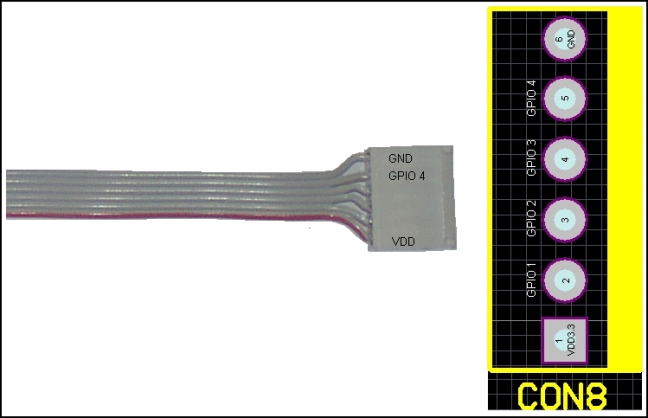

Theory of operation: The wind vane or rudder attaches to a shaft on the anemometer

head. The anemometer shaft turns a potentiometer inside the head. The potentiometer

produces a voltage between 0 and 3.2 that varies linearly with azimuth. The voltage is

transmitted over 2 wires back to one of the RMS-200 voltmeters. The diagram below shows the

recommended mounting, with the wind vane arm pointing North out from the mast. Before

attaching the vane or rudder, turn the shaft so that the voltage reading is 0 volts, then

attach the vane as shown below.

Software Overview

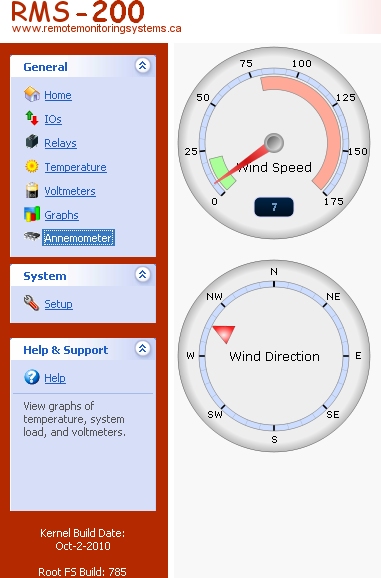

Below is a screen shot of the RMS-200 Davis 7911 anemometer interface. Two gauges show both

wind speed and direction.

The download zip file below contains all of the files needed to display the gauges. Simply

download the files and extract them to your computer. With FTP, upload the files to the

RMS-200 board at /data/custom/. Go to the RMS-200 setup area and add a custom device. In

the "path to custom file" box, enter: custom/anemometer.php and click the OK button. An

anemometer icon will be displayed in the left navbar as shown above. Edit the aserver.php

file to set which voltmeter is used for the wind direction.

Make the anemometer daemon executable by typing on the command line: chmod 755

/data/custom/anemometerd

Start the anemometer daemon (anemometerd gpio_number). To get usage info on the anemometer

daemon, run it without arguments. When the anemometer daemon is running it will create the

wind speed file in /var/rmsdata/a-count.

This concludes the anemometer GPIO project. We can now monitor our wind speed and direction

from the comfort of home or at the office with the RMS-200 remote site monitoring

board.

Our Story

EtherTek Circuits started its business in 2001. Ever since we have provided remote monitoring and control solutions for Remote Tower Sites, the Oil & Gas industry, Telemetry systems for Agriculture, Municipalities, Mines, Solar Farms, Hydro Plants, and the Military.

Anemometer files

Anemometer files